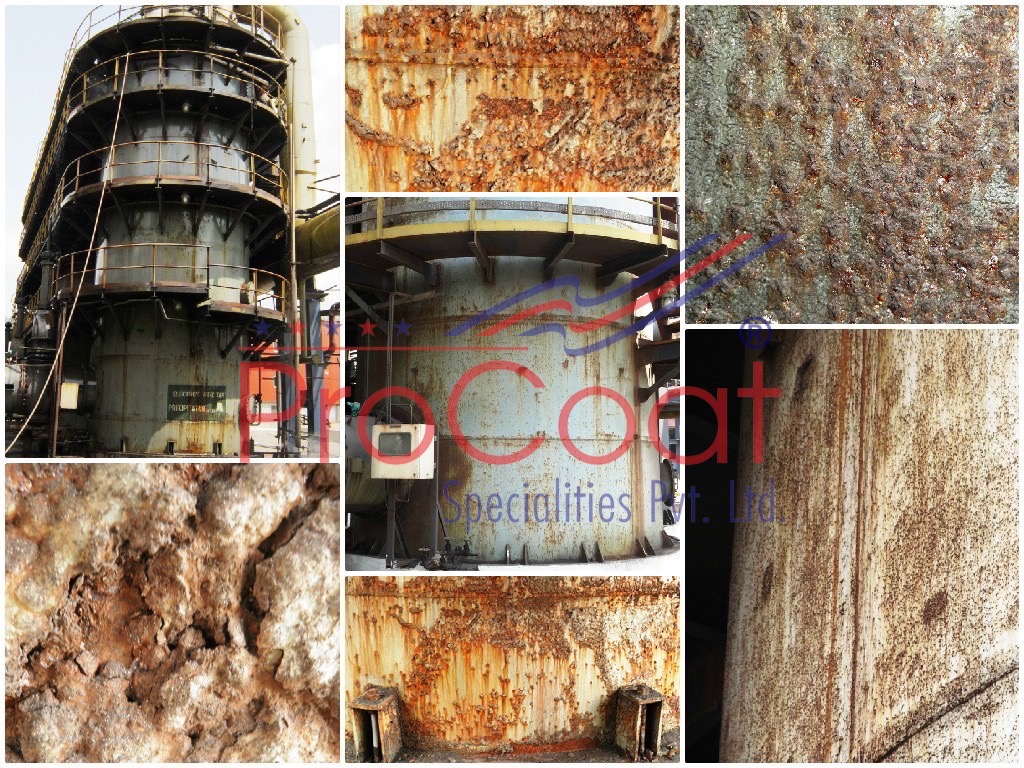

External surface of these Electrostatic Tar Precipitators are constantly in contact with vapours of ammonia which is being liberated from the surrounding process equipments. Though the ETP surface has been painted with conventional paint system yet great amount of corrosion is observed.

Initially the surface was neutralized by means of water washing and scrubbing the surface to eliminate the deposited traces of corrosion causing elements.

The neutralized surface was thoroughly blast cleaned using copper slag abrasive medium to SA 2.5 surface profile to near white metal finish ensuring the surface is also free from adsorbed contaminants.

Over the prepared surface, ProCoat coating was applied using Airless Spray Method to evenly deposit the material all over the surface. This method was adopted not only to apply the coating material evenly, but also not to expose the prepared metal surface for longer periods of time to the vapours of Ammonia which gets continuously expelled into the working environment. Intermittent checks were made using Elcometer WFT gauge to ensure the desired thickness of coating as per the requirements.

Once the coating was cured Dry Film Thickness was measured using the Elcometer DFT Gauge & checked with Holiday Spark Testing to ensure coating integrity. Six such Electrostatic Tar Precipitators have been coated using ProCoat Advanced Polymer Coating Systems providing the reliable protection to these equipments for almost three years now.