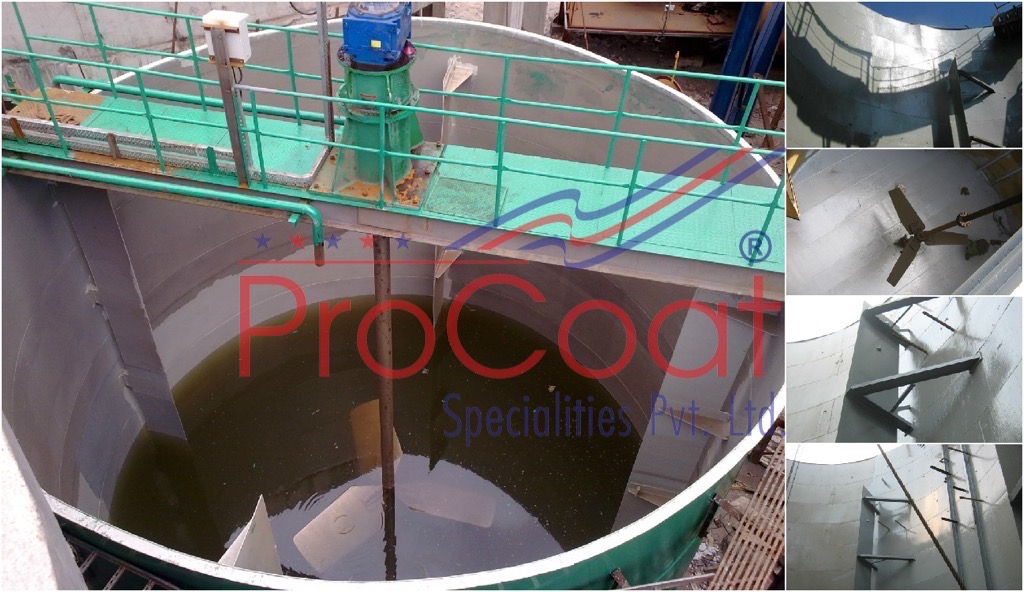

These newly fabricated mild steel tanks were intended for storing sludge which comes out after the operational process inside scrubber vessel of the steel making industry. The sludge which is a thick fluid with solid particles along with high temperature that has an abrading & corroding action over the internal surface of this mild steel tank. Keeping in view the proven performance of ProCoat Coatings & Quality Application Methods in safe-guarding the internal surface of various equipments, the client chose ProCoat Coating Systems entrusting the reliability and durability showcased.

Initially the protruding weld beads were removed using the a grinding machine making the surface even. Thereupon the surface was blast cleaned using chilled iron grit to ensure the desired surface roughness of an average 100+ microns to Sa 3 Swedish Standards, prior to coating application. In order not to expose the blast cleaned surface to open air atmospheric conditions of the plant, portion by portion of the tank was addressed by blast cleaning and immediately followed up with coating works over these 11 meter tall tanks. To access the entire surface of the tank ladders and suspended platforms were utilised abiding to all the safety norms. The coating was checked for thickness levels using Elcometer WFT Gauge intermittently and cross-verified using Elcometer DFT Gauge on curing. Holiday Spark Testing was carried out over the entire surface of tank to make sure rigid coating integrity without any flaws.

After completion of the coating works, the tank was put into operations for storing the sludge. These tanks were coated in the year 2011 and since then a convincing & durable protection is being catered to the metal surface comprehensively.