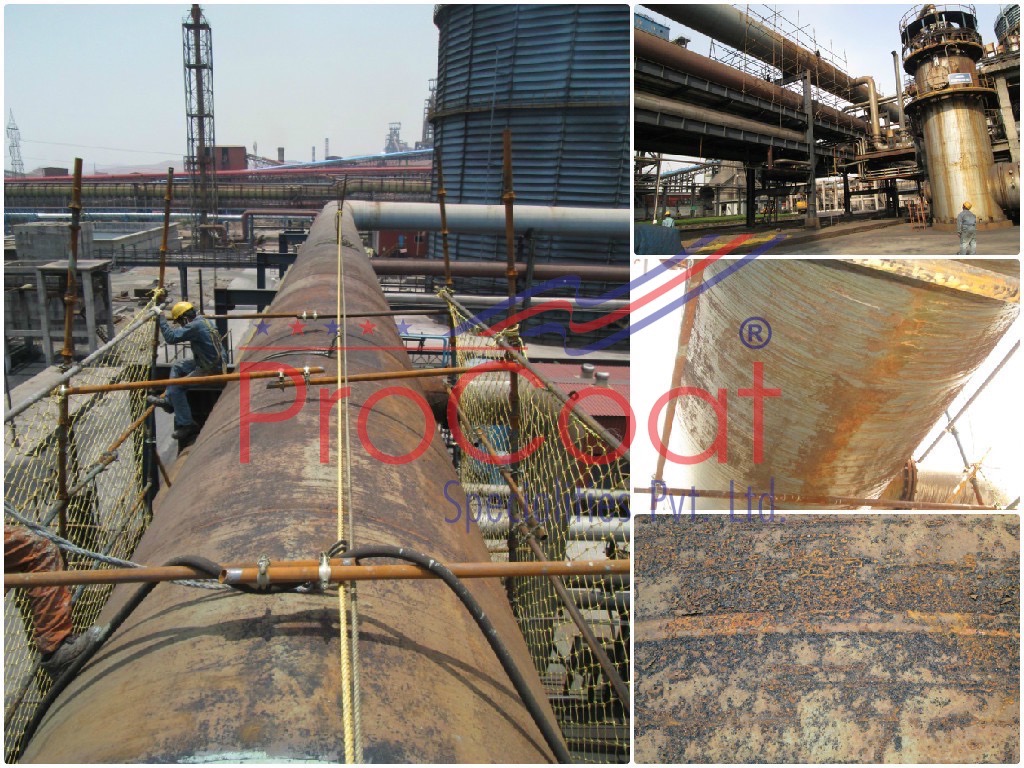

These pipeline external surface is in continuous contact of the gaseous chemicals emanated from the process equipments in a coke oven plant. Though the pipeline surface has been painted earlier yet over a short period of time the metal surface has been corroding due to the failure of paint and prevailing operating conditions.

The surface of this pipeline was blast cleaned initially & checked for the presence of adsorbed salts, and thereby relevant methods were incorporated for removing the contamination by means of detergent cleaning, second round of blast cleaning and neutralizing the surface with thorough water jetting cleaning ensuring a rough, contamination free surface to the desired surface profile.

Over the prepared surface, application of ProCoat Coating System was carried out using rollers. The coating deposited over the surface was checked for complete and firm adhesion to the desired thickness which was measured using various Wet Film & Dry Film Gauges followed up with Spark Testing to enhance coating integrity.

Proper planning, quality workmanship & safe work methods followed have resulted in performance of the coating applied over the pipeline surface to resist the severe corrosive conditions since almost five years now.